- Dry Ice Detailing is now available

- By Appointment ONLY

Welcome to Carzwerk, where we bring you the captivating world of dry ice detailing! Prepare to embark on a journey that combines cutting-edge technology with the enchanting power of frozen carbon dioxide. Dry ice detailing, a revolutionary cleaning and rejuvenation technique, is here to elevate your expectations and transform the way you perceive automotive care.

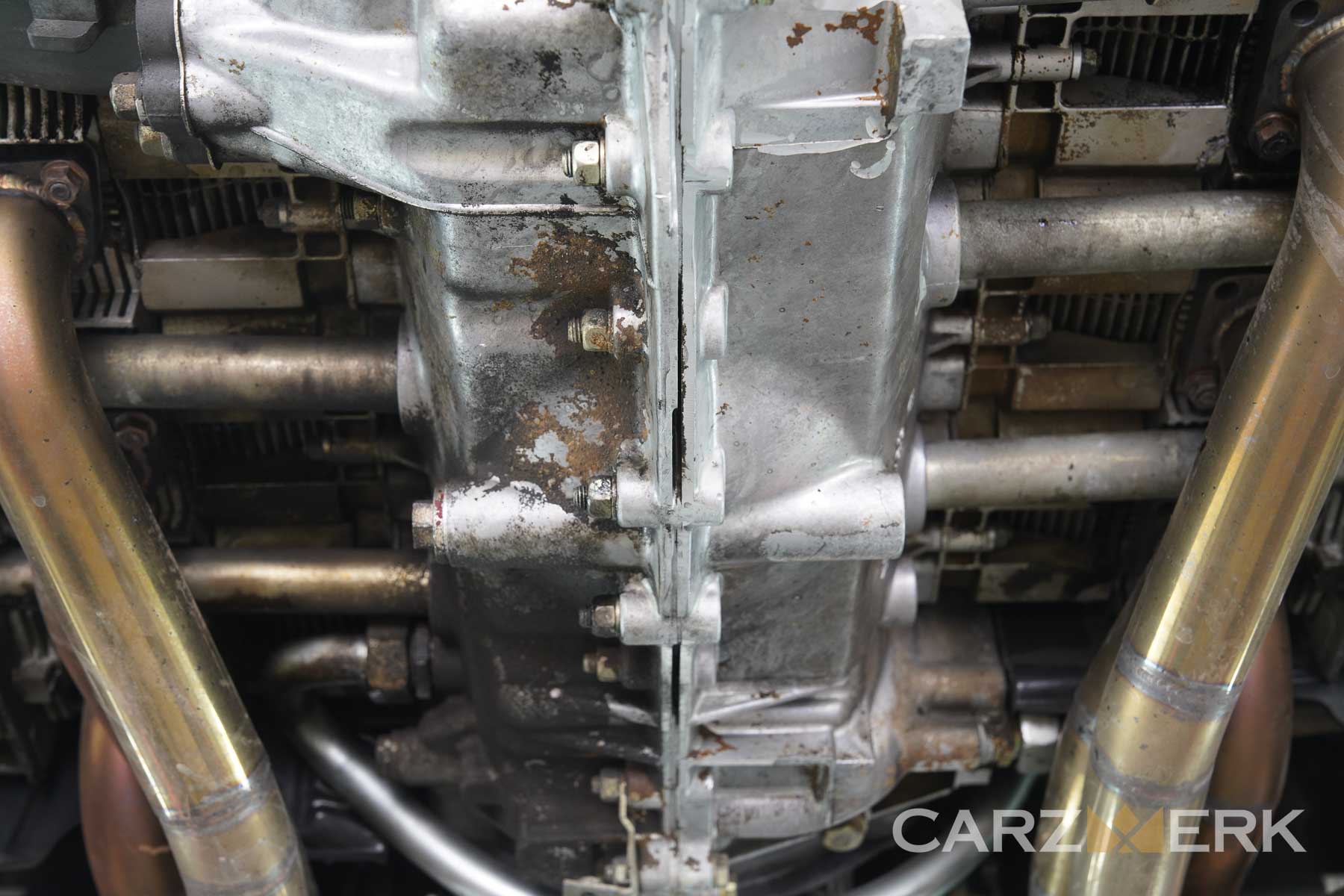

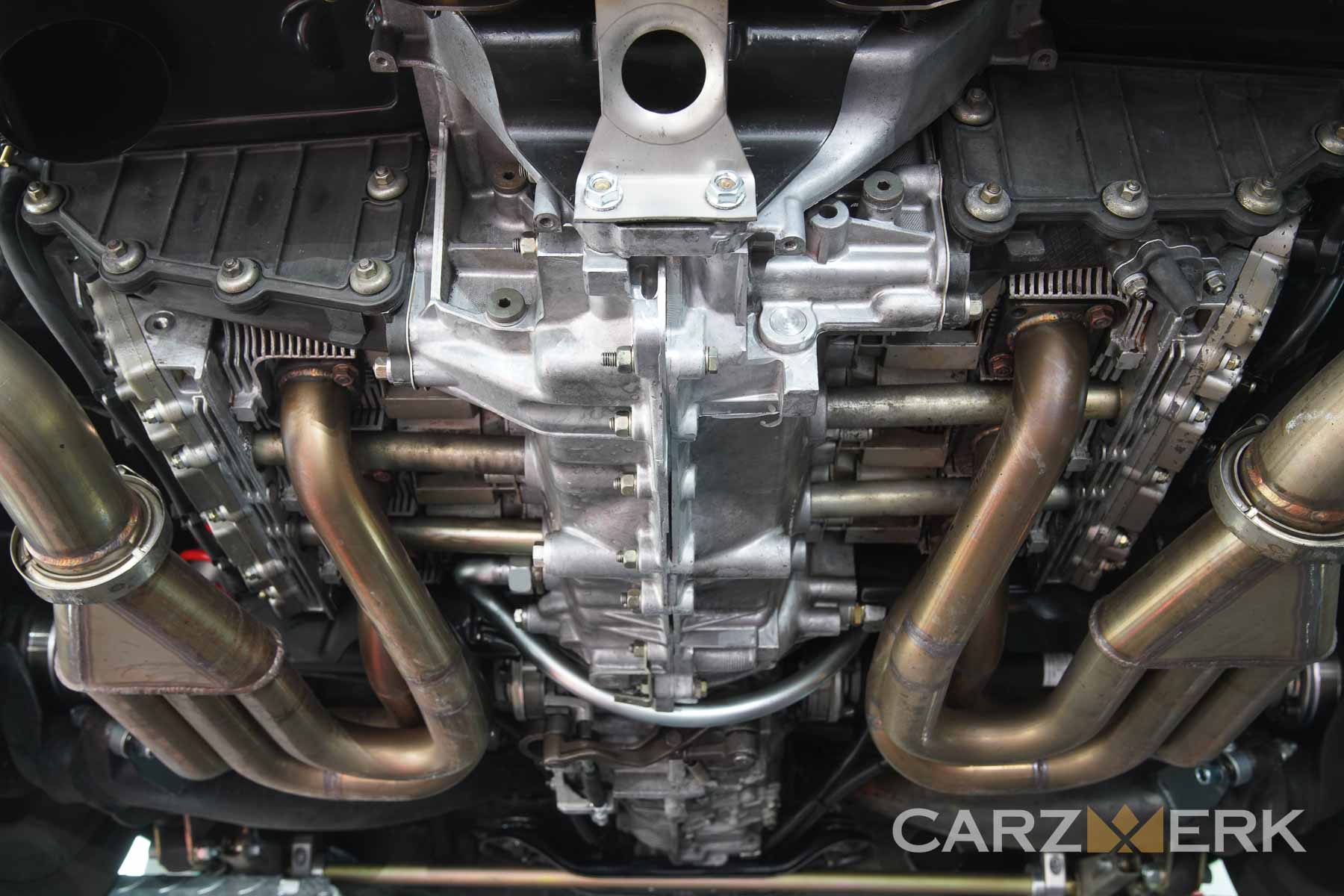

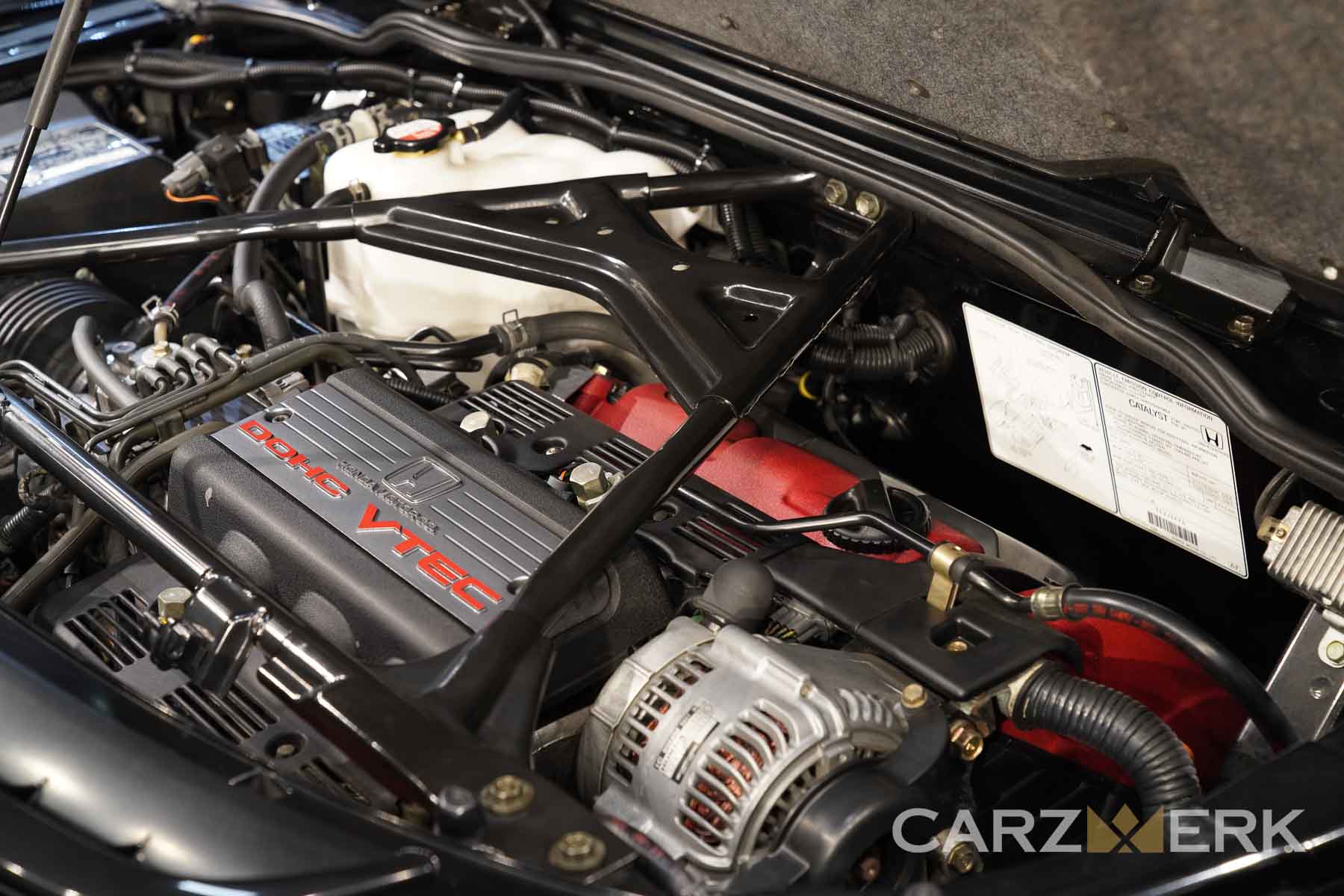

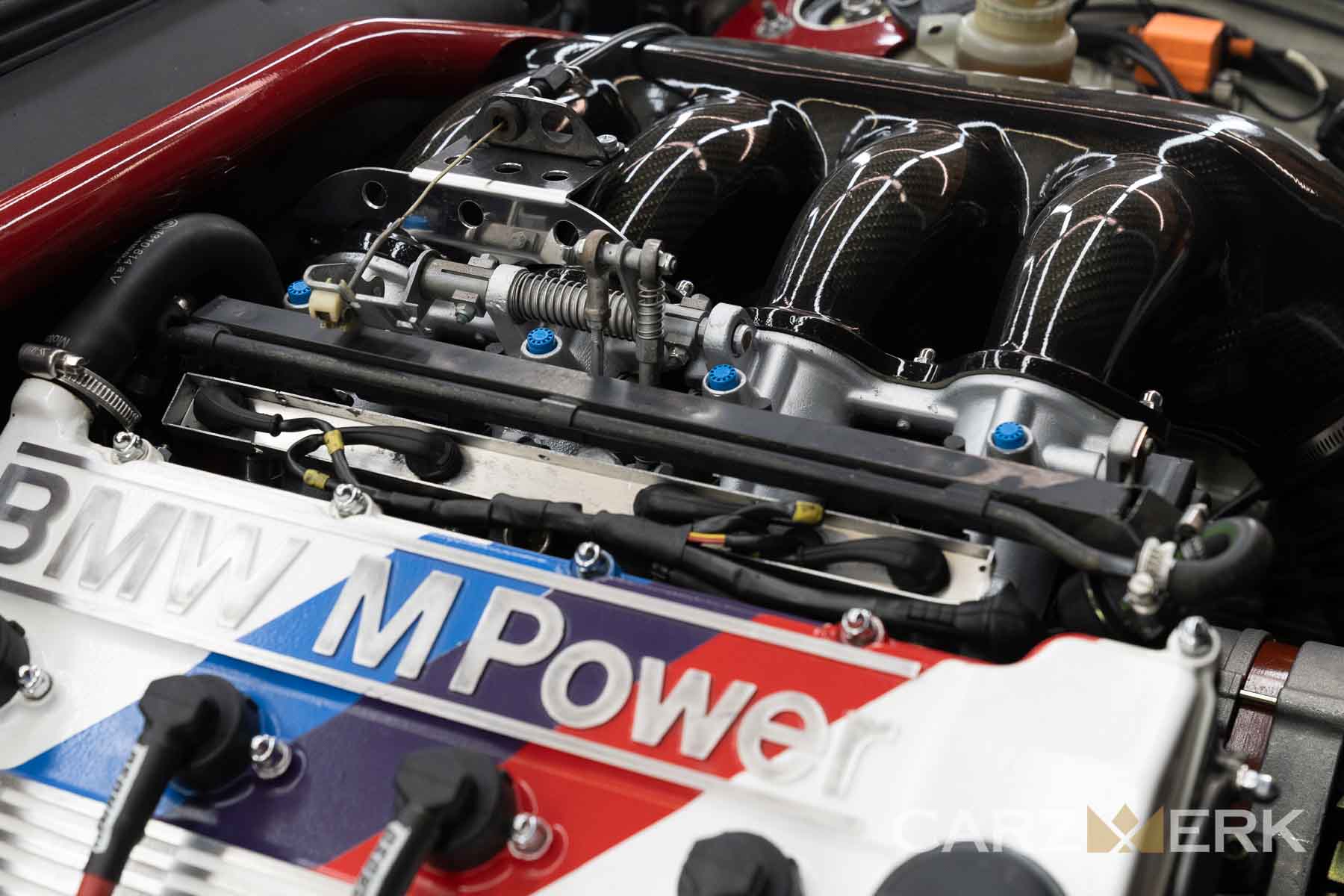

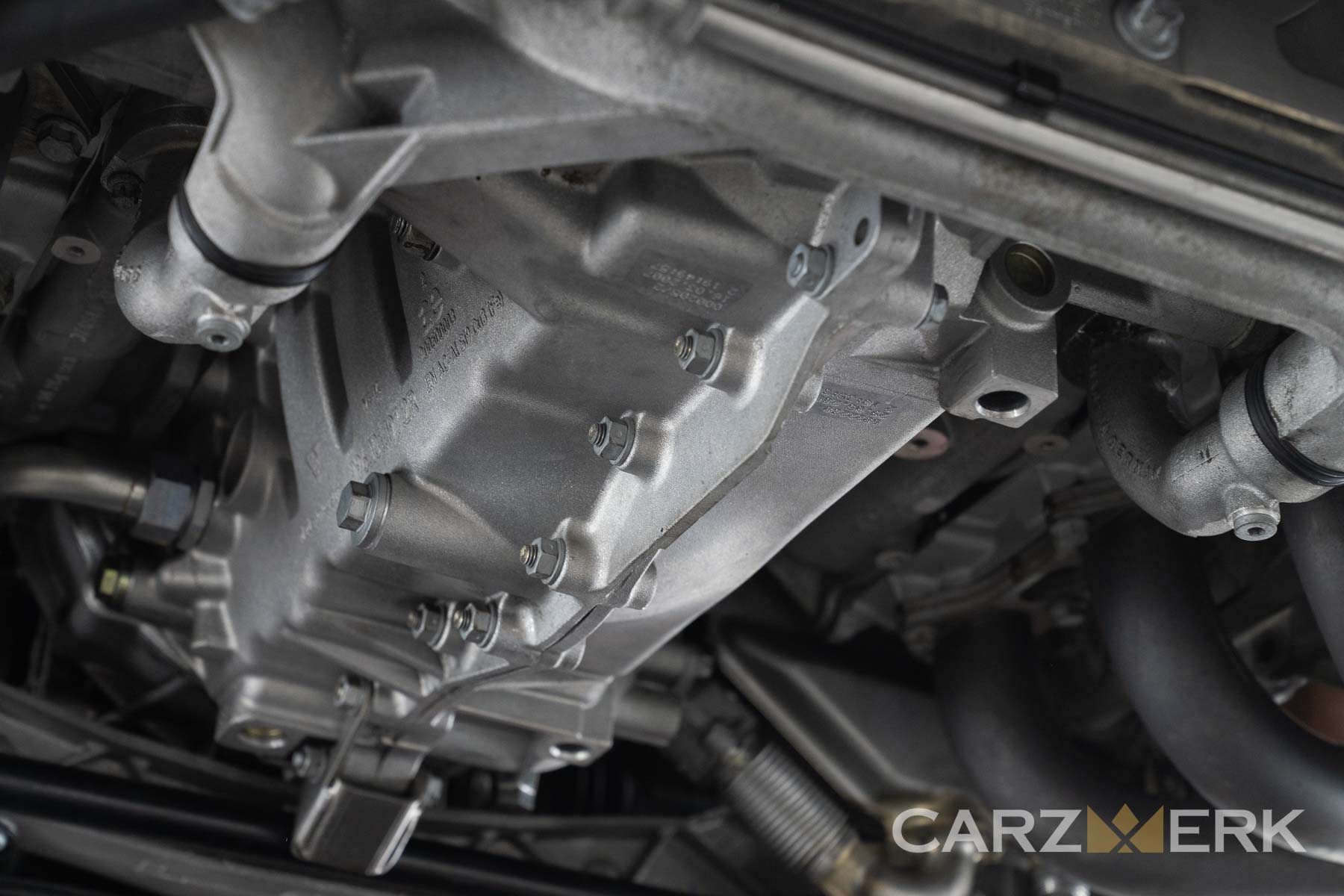

Dry ice detailing is a quick, safe, and efficient clean a variety of automotive components during your restoration or cleaning project in Fremont, CA – SF Bay Area

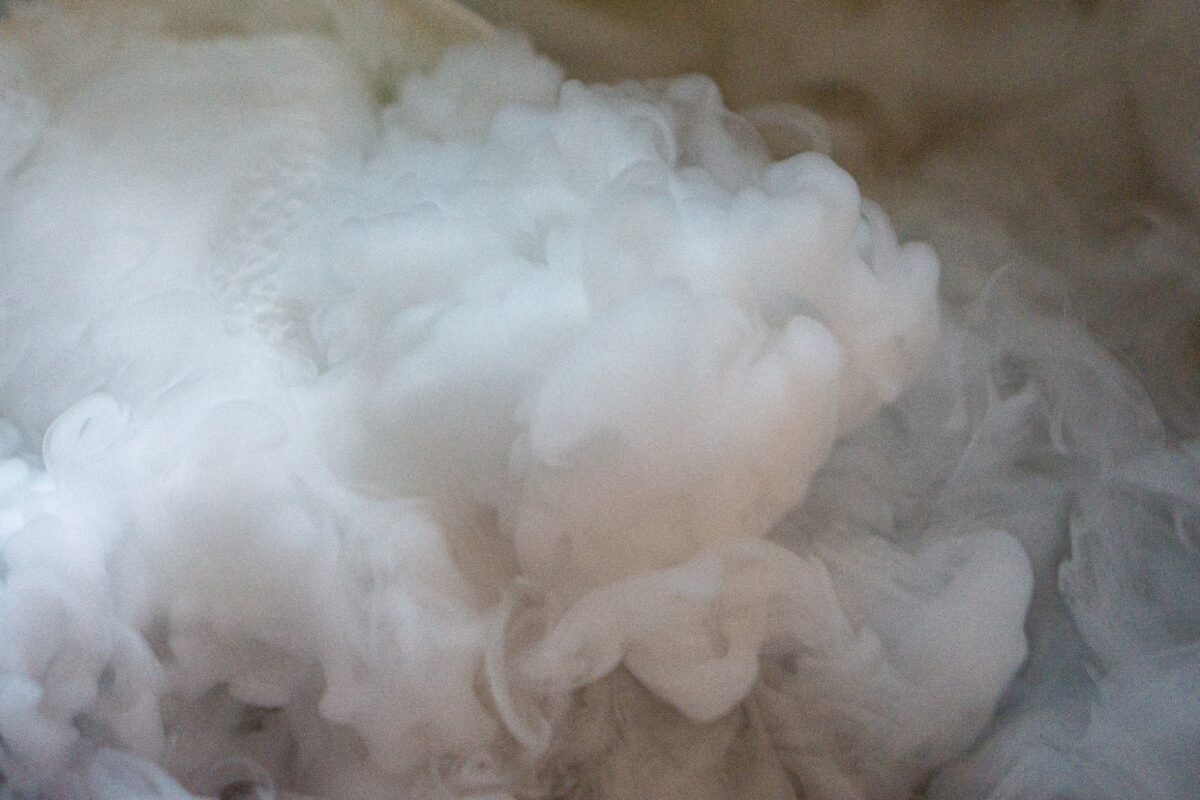

Picture this: a cloud of white mist gently enveloping your vehicle, as the dry ice works its magic, removing dirt, grime, and imperfections with astonishing precision. This innovative method, also known as “cryogenic cleaning,” harnesses the incredible properties of dry ice, which transforms from solid to gas without leaving any residues, ensuring an eco-friendly and residue-free shine.

As opposed to traditional detailing methods, dry ice detailing delivers unparalleled results without the use of water, harsh chemicals, or abrasive tools. Embracing sustainability and environmental consciousness, this process minimizes waste, making it the ultimate choice for those seeking an eco-conscious automotive care solution.

Dry ice, scientifically identified as solid carbon dioxide (CO2), transcends the conventional realm of frozen substances with its unique characteristics and versatile applications. Unlike the familiar frozen water that melts into a liquid, dry ice undergoes a fascinating transformation directly from a solid to a gas, a phenomenon known as sublimation. This distinctive property makes dry ice a substance of choice for various practical and specialized uses across various industries.

One of the most common applications of dry ice is in the realm of preserving perishable items. Its sublimation process, which transitions directly from a solid to a gas without a liquid phase, makes it an ideal cooling agent. When placed in a container with perishable goods, dry ice not only maintains a sub-zero temperature but also ensures a dry environment, preventing unwanted moisture buildup. This preservation quality is particularly valuable in transporting and shipping temperature-sensitive items like frozen foods, medical specimens, and pharmaceuticals.

Beyond its role in preserving perishables, dry ice finds extensive use in the entertainment industry, where its ability to create a dramatic visual impact is harnessed for special effects. The dense, cold vapor produced during sublimation produces a captivating, fog-like effect that enhances the atmosphere in theatrical productions, concerts, and haunted houses. Its smoke-like appearance adds an element of mystique, making it a favorite tool for stage managers, event planners, and filmmakers.

Additionally, dry ice is a crucial component in various scientific and industrial processes. In laboratories, it serves as a cooling agent for sensitive equipment and specimens, ensuring that temperatures remain consistently low. In industrial cleaning applications, dry ice blasting utilizes the pressurized force of dry ice pellets to clean surfaces without generating secondary waste, making it an environmentally friendly alternative to traditional cleaning methods.

Moreover, the culinary world has embraced dry ice for its ability to create a visually stunning and interactive dining experience. Chefs use it to produce impressive smoke or fog effects for presentations and to rapidly freeze or chill ingredients for avant-garde culinary creations.

Our team of skilled technicians, armed with the latest dry ice detailing machine, will pamper your vehicle, bringing out its true essence and restoring its original glory. The benefits of dry ice detailing extend beyond mere aesthetics – it can also help prolong the life of your car’s surfaces and protect its resale value.

But dry ice detailing isn’t limited to cars alone! Its versatility extends to a wide range of applications, from motorcycles and boats to industrial equipment and delicate household items. No surface is too tough or too delicate for the wonders of dry ice cleaning. At Carzwerk, you can experience the future of automotive care with us, and prepare to be amazed by the transformative power of dry ice detailing.

Explore our website to learn more about the science behind this captivating process, the multitude of applications it offers, and the testimonials from our delighted clientele. Join us on this thrilling adventure, and together, let’s unleash the full potential of dry ice detailing

Solid carbon dioxide is not for amateurs. Due to its elemental structure and surface temperature of -109.3 degrees Fahrenheit, it needs to be safely handled. Its potential hazards include asphyxiation, frostbite, and pressure explosion. Who knew?! The substance requires a set of guidelines to be followed, such as this one listed by Cayman Dry Ice. Luckily, we have summarized it for you.

Here are some things you can do to prevent these hazards:

Our highly skilled team can complete your dry ice auto detailing and other services if you’re based in Fremont, California, or the San Francisco Bay Area. If you’re in the vicinity or want to make the trip, give us a shout so we can assess what kind of services suit your needs.